Methods for Making Large-area, Free-standing Poly-crystalline Diamond Films

Low cost methods to produce poly-crystalline diamond (PCD) membranes with adjustable dimensions for use in electronic/mechanical/optoelectronic devices.

Due to its unique combination of outstanding physical and chemical properties, such as wide band-gap, chemical inertness, the highest hardness and thermal conductivity, negative electron affinity, and biocompatibility, carbonaceous materials (e.g. poly-crystalline diamond (PCD)) are considered to be promising materials for applications in electronic and micro-electromechanical devices, biomedical sensors, electrochemical electrodes, and field electron emission (FEE) devices. For such a carbonaceous material to be reliably and efficiently used in any of the various applications, a process to form the carbonaceous material as a membrane with adjustable dimensions is desirable. Conventional approaches to fabricate PCD membranes have several limits and restrictions that prohibit the realization of large-scale and high-quality PCD membrane production.

University at Buffalo and Fraunhofer USA researchers developed various methods for making a large-scale and high-quality PCD membrane that can have a free-standing and transferrable form. In a brief overview, a sacrificial layer (e.g., a silicon dioxide (SiO 2) layer) is first formed on a (e.g. silicon (Si)) substrate, followed by forming a PCD layer, according to various embodiments. Next, the sacrificial layer is selectively removed to physically separate the PCD layer from the substrate. Given that this PCD membrane can be transferred using one of various micro-transfer printing techniques, the PCD membrane can be easily placed/located at any desired location to form various PCD membrane based heterostructures. For example, the PCD membrane can be integrated into any suitable electronic/mechanical/thermal/optoelectronic device.

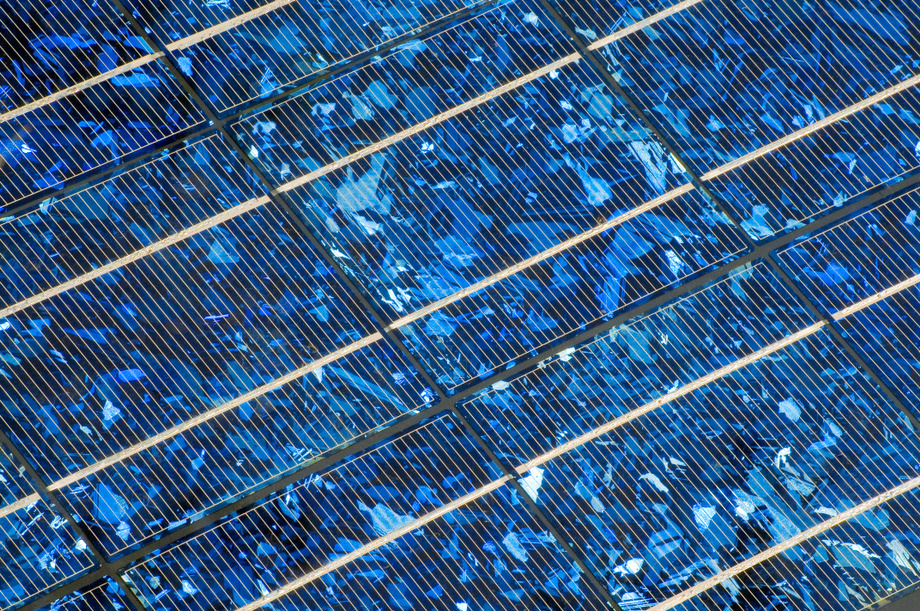

Source: mahey, https://stock.adobe.com/uk/, stock.adobe.com

Source: mahey, https://stock.adobe.com/uk/, stock.adobe.com

- Lower cost production.

- Adjustable dimensions.

- Electronic and micro-electromechanical devices

- Biomedical sensors

- Electrochemical electrodes

- Field electron emission (FEE) devices

US Patent Application 18/075,345 filed December 5, 2022.

Lab scale demonstration.

Licenses and research collaboration through Fraunhofer USA.

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|