Nature-inspired Functionally-graded UHMWPE + Kevlar Composites Achieve Extraordinarily High Strength

Nature-inspired polymers are achieved using unique processing to yield functional gradient composites with embedded Kevlar fibers exhibiting extraordinarily high strength lightweight UHMWPE materials.

Demand for new energy absorption materials and implantable polymeric biomaterials has increased significantly in recent years. The personal protective equipment (PPE) industry seeks materials with improved impact resistance and impact attenuating performance. Manufacturers are embracing trends in new materials such as aramid and ultra-high molecular weight polyethylene (UHMWPE) to achieve high strength-to-weight ratios. The orthopedic implant market needs high strength, lightweight biocompatible materials that enable personalized implants that prevent surgical readmission due to dislocation, periprosthetic fracture, and mechanical loosening. UHMWPE-based implants have gained popularity in applications such as orthopedic and cardiovascular implants due to the material's long-life span and tensile strength.

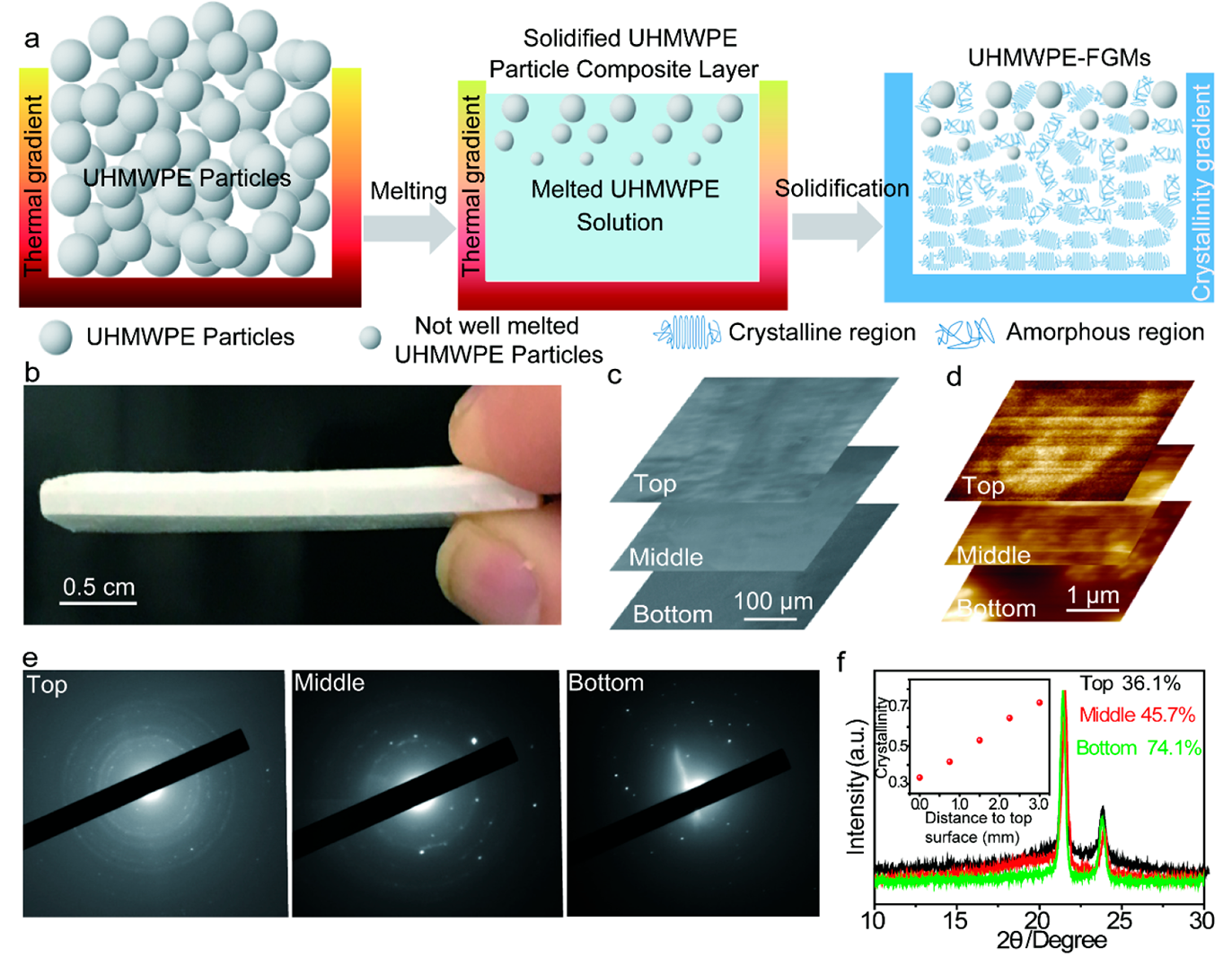

University at Buffalo researchers have developed methods of using an "autoclave-like" compression molding technique that creates a functional gradient in a UHMWPE + Kevlar fiber composite that is scalable for high volume production of structural shapes. Functionally-graded UHMWPE material mimics nature (bones, teeth, crustacean nacre) absorbing energy with good impact resistance. It displays greater impact resistance when impact occurs on the more crystalline face instead of the less crystalline face. The melt and solidification process of UHMWPE leads to morphological and structural variations along the vertical direction of the resulting material. More specifically, the top layer of the UHMWPE exhibits percolated structures, while lower sections of the UHMWPE correspond to semitransparent and homogeneous structures. The process involves several steps whereby UHMWPE powder and co-axially oriented Kevlar fibers are heated under pressure to create a functionally graded composite with significantly higher impact strength than existing solutions.

Figure 1. Fabrication, morphology, and structure of the functionally-grade material (FGM) UHMWPE-FGMs. (a) Schematic illustration of UHMWPE-FGM fabrication procedure. (b) A photograph of a resulting UHMWPE-FGM sample. (c) SEM images of a UHMWPE-FGM sample at different points along the thickness direction (top, middle, and bottom). (d) AFM images of UHMWPE-FGMs at various regions along the thickness direction (top, middle, and bottom). (e) SAED images of UHMWPE-FGMs at various depth along the thickness direction (top, middle, and bottom). (f) XRD patterns UHMWPE-FGMs at various depth along the thickness direction. All statements about crystallinity percentages based on analysis of XRD patterns.

Figure 1. Fabrication, morphology, and structure of the functionally-grade material (FGM) UHMWPE-FGMs. (a) Schematic illustration of UHMWPE-FGM fabrication procedure. (b) A photograph of a resulting UHMWPE-FGM sample. (c) SEM images of a UHMWPE-FGM sample at different points along the thickness direction (top, middle, and bottom). (d) AFM images of UHMWPE-FGMs at various regions along the thickness direction (top, middle, and bottom). (e) SAED images of UHMWPE-FGMs at various depth along the thickness direction (top, middle, and bottom). (f) XRD patterns UHMWPE-FGMs at various depth along the thickness direction. All statements about crystallinity percentages based on analysis of XRD patterns.

- High strength (specific strength is 14x larger than steel)

- High impact strength - desirable for structural applications, such as biomedical implants, personal or vehicle protection equipment

- Lightweight (density < water)

- High thermal conductivity

- Exceptional biocompatibility and chemical stability

- Low moisture absorption

- Chemical resistant (Excluding oxidizing acids)

- Low dielectric constant

- FDA compliant

- Low coefficient of friction

- Self-lubricating

- Resistant to UV radiation

- Personal protective equipment - Helmets, body, military, sports & athletics, first responders, law enforcement

- Vehicle and infrastructure protective equipment

- Vehicle light-weighting

- Orthopedic and Biomedical implants - Neck, Spine, Hip or Shoulder Replacement, Dental

- Additive manufacturing of personalized, customized protective equipment

US Patent Application 17/360,660 filed June 28, 2021. US20220072743A1

Demonstration of process and methods and sample materials in composite sheet form

Available for licensing or collaboration.

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|